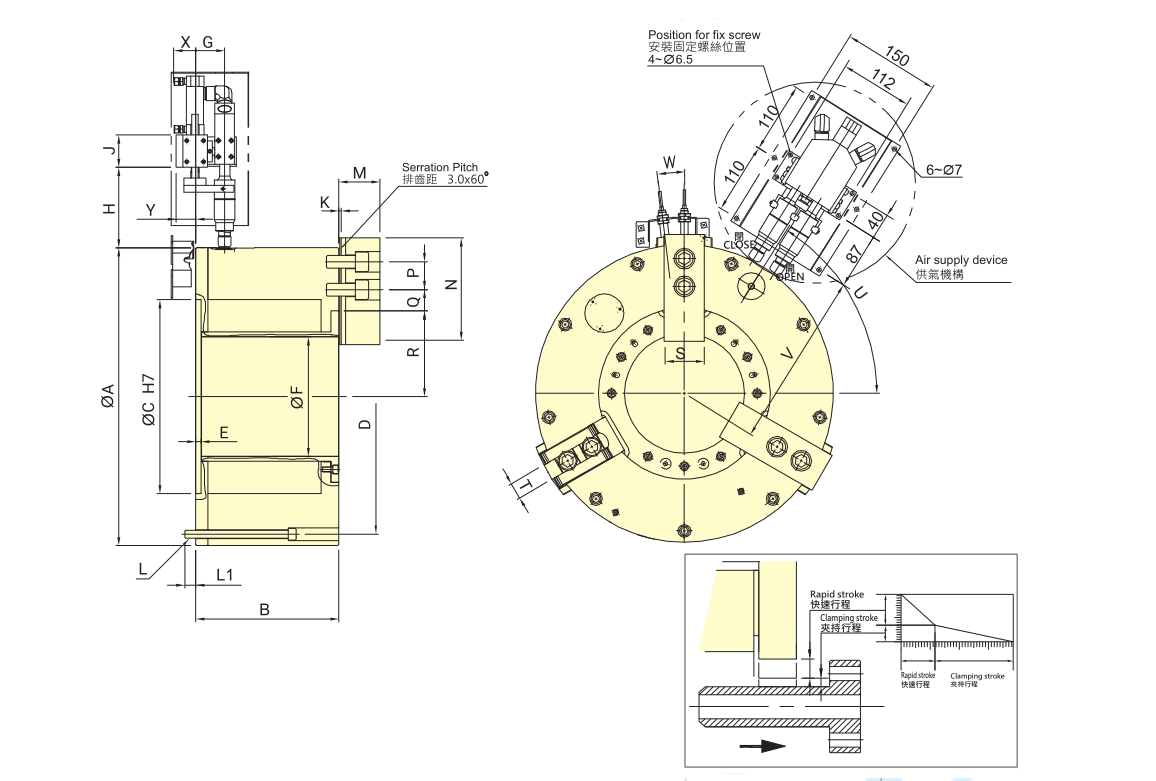

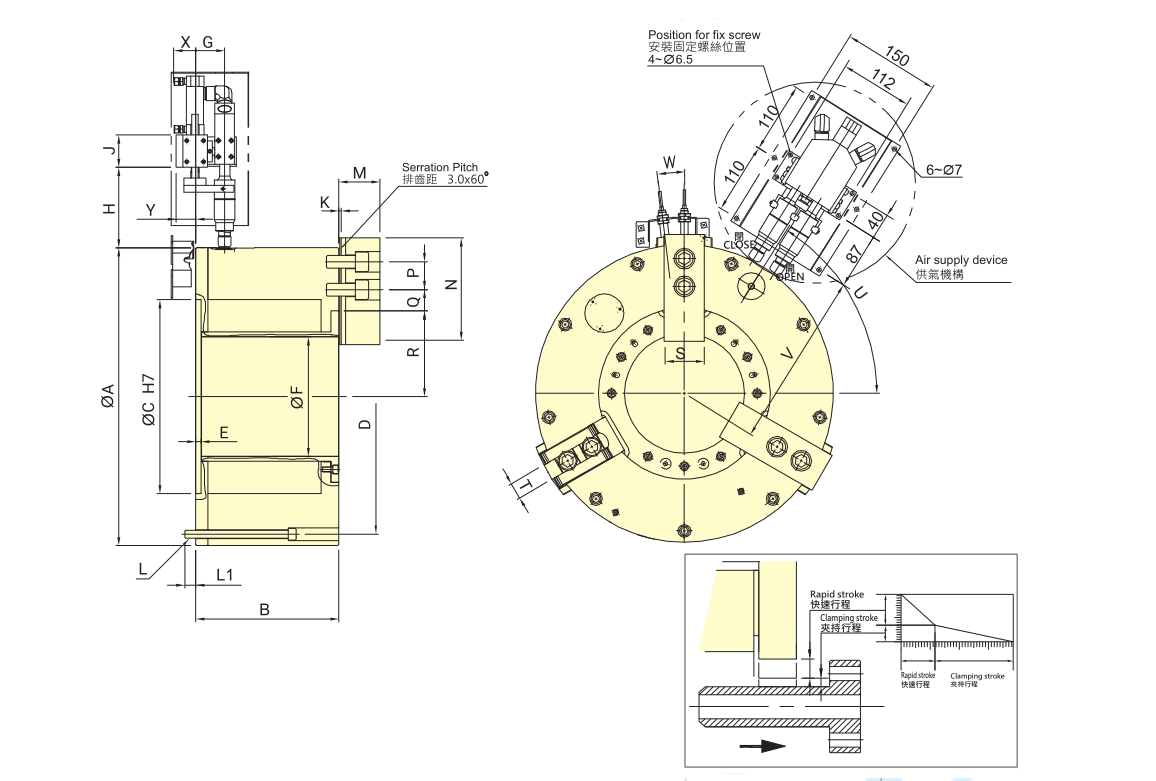

Large through-hole 3-jaw power chuck with built- in air cylinder.

With built-in "pressure detection" device which can check the rapidly decreasing pressure within the chuck, guarantee to the security when operating.

Patented air supply system, it is easy to install and maintain. No abrasion issue of traditional sealed ring. Maintenance cost and time can be saved.

The build-in "clamping detection" device can avoid jaws clamping the workpiece during the rapid stroke stage. This mechanism can also prevent causing the damage of the internal parts or flying out of workpiece.(only for external clamping).

Extended jaw stroke design can shorten the processing time when gripping.

Notice: No enough clamping force in rapid stroke period.

Size unit: mm

|

Model

|

Thru-hole Dia.(mm)

|

Jaw stroke

(Dia.) (mm)

|

Chucking Dia.

Max. (mm)

|

Chucking Dia.

Min. (mm)

|

Gripping Force

(at 0.6 Mpa) kN (kgf)

|

|

APS-185

|

185

|

26/14

|

460

|

127

|

110(11216)

|

|

Model

|

Liter Air?Consumption

(at 0.6 Mpa)

|

Max. speed

min-1(r.p.m.)

|

Moment of Inertia

kg?m2

|

Weight (kg)

|

|

APS-185

|

22

|

1300

|

6.45

|

198

|

|

Model

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

J

|

K

|

L

|

L1

|

M

|

N

|

P

|

|

APS-185

|

460

|

221

|

300

|

425

|

8

|

185

|

45

|

124

|

50

|

3.5

|

9~M12

|

17

|

63.7

|

165

|

43

|

|

Model

|

Q max.

|

Q min.

|

R max.

|

R min.

|

S

|

T

|

U

|

V

|

W

|

X

|

Y

|

|

APS-185

|

37

|

17

|

145

|

125

|

62

|

25.5

|

58

|

272

|

7°

|

38

|

30

|

Subject to technology changes without prior information

Non-standard requirements can be made