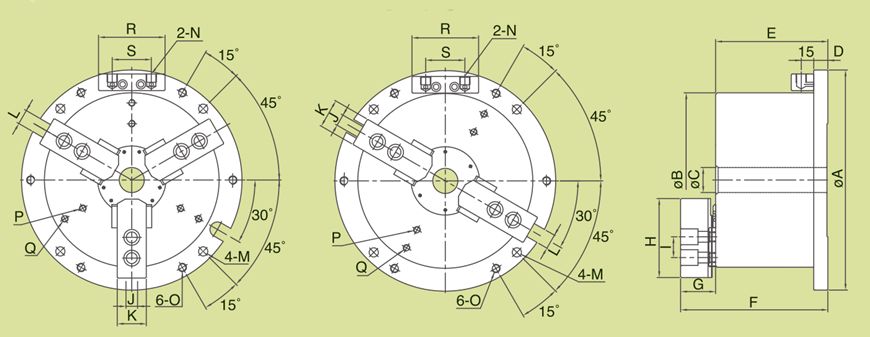

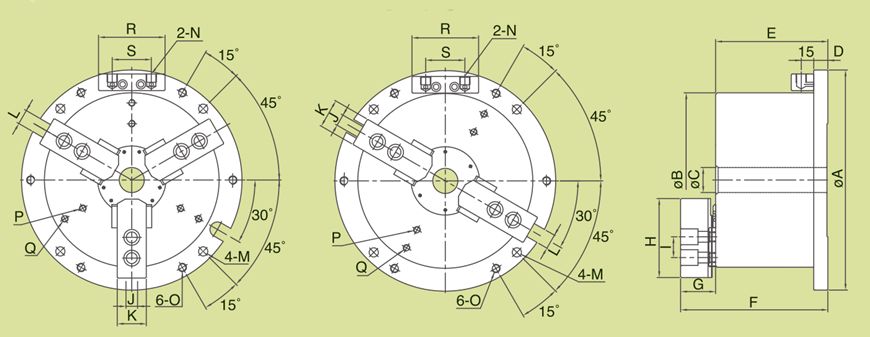

L: Long stroke

With built in type cylinder, it is ideal for machining application on working table.

1,Rust-proof for pneumatic cylinder: inside wall of the cylinder being rustproof treated; the cylinder can work under the condition of wet and high moisture circumstances, and without rusty and stucked

2,Dusts-proof and water proof: the structure can prevent work chips and coolant water from entering into chuck cylinder, so its accuracy can be maintained, the service life will be longer

3,Benefits of built in cylinder: The cylinder is connected to chuck body directly for obtaining better stability, high clamping force, it's applicable for heavy turning and high accuracy and high effeciency demand.

|

Spec/ Model

|

Piston Area

cm2

|

Piston stroke

mm

|

Jaw stroke Dia.

mm

|

Max clamping force

kgf

|

|

MO-04

|

57

|

9

|

3.8

|

23.5

|

|

MO-05

|

74

|

10

|

5.4

|

32.2

|

|

MO-06

|

97

|

12

|

5.5

|

49.4

|

|

MO-08

|

156

|

16

|

7.4

|

79.4

|

|

MO-10

|

235

|

19

|

8.8

|

119.7

|

|

MO-12

|

292

|

23

|

10.6

|

142.1

|

|

ML-08

|

156

|

16.5

|

12

|

51

|

|

MOT-04

|

57

|

9

|

3.8

|

18.6

|

|

MOT-05

|

74

|

10

|

5.4

|

25.6

|

|

MOT-06

|

97

|

12

|

5.5

|

39.5

|

|

MOT-08

|

156

|

16

|

7.4

|

63.5

|

|

MOT-10

|

235

|

19

|

8.8

|

95.6

|

|

Spec/Model

|

Max.oil pressure

Kgf/cm2

|

Gripping force

at 0.7MPa

KN

|

Weight

kg

|

Gripping Range

mm

|

|

MO-04

|

15

|

10.8

|

7.05

|

9-115

|

|

MO-05

|

20

|

12.7

|

11.2

|

12-135

|

|

MO-06

|

20

|

19.6

|

21

|

15-169

|

|

MO-08

|

20

|

32.3

|

36.8

|

20-210

|

|

MO-10

|

20

|

47

|

56.4

|

33-254

|

|

MO-12

|

20

|

50

|

88.5

|

40-304

|

|

ML-08

|

20

|

18

|

37.6

|

20-210

|

|

MOT-04

|

12

|

10.8

|

6.9

|

9-115

|

|

MOT-05

|

16

|

12.7

|

11.2

|

12-135

|

|

MOT-06

|

16

|

19.6

|

21

|

15-169

|

|

MOT-08

|

16

|

32.3

|

36.8

|

20-210

|

|

MOT-10

|

16

|

47

|

56.4

|

33-254

|

|

Spec/Model

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

I

|

|

MO-04

|

157

|

115

|

|

15

|

77.5

|

104

|

26

|

49.5

|

14

|

|

MO-05

|

185

|

135

|

|

15

|

95

|

128

|

33

|

62

|

14

|

|

MO-06

|

224

|

169

|

25

|

16

|

118

|

158

|

40

|

73

|

20

|

|

MO-08

|

265

|

210

|

30

|

20

|

138

|

180

|

42

|

95

|

25

|

|

MO-10

|

315

|

254

|

52

|

23

|

150

|

196

|

46

|

110

|

30

|

|

MO-12

|

375

|

304

|

80

|

23

|

165

|

219

|

54

|

129

|

30

|

|

ML-08

|

264

|

210

|

30

|

20

|

138

|

180

|

42

|

95

|

25

|

|

MOT-04

|

157

|

115

|

|

15

|

77.5

|

104

|

26

|

49.5

|

14

|

|

MOT-05

|

185

|

135

|

|

15

|

95

|

128

|

33

|

62

|

14

|

|

MOT-06

|

224

|

169

|

25

|

16

|

118

|

158

|

40

|

73

|

20

|

|

MOT-08

|

265

|

210

|

30

|

20

|

138

|

180

|

42

|

95

|

25

|

|

MOT-10

|

315

|

254

|

52

|

23

|

150

|

196

|

46

|

110

|

30

|

|

Spec/Model

|

J

|

K

|

L

|

M

|

N

|

O

|

P

|

Q

|

R

|

S

|

|

MO-04

|

10

|

23

|

13

|

9(PCD 135)

|

PT1/8

|

M8

|

3-M8(PCD 90)

|

|

64

|

47

|

|

MO-05

|

10

|

25

|

13

|

9(PCD 165)

|

PT1/4

|

M8

|

3-M8(PCD 100)

|

|

80

|

47

|

|

MO-06

|

12

|

31

|

18

|

11(PCD 202)

|

PT1/4

|

M10

|

3-M8(PCD 134)

|

|

80

|

47

|

|

MO-08

|

14

|

35

|

18

|

11(PCD 243)

|

PT1/4

|

M10

|

3-M10(PCD 136)

|

3-M10(PCD

186)

|

80

|

47

|

|

MO-10

|

16

|

40

|

18

|

13(PCD 285)

|

PT1/4

|

M12

|

3-M12(PCD 170)

|

3-M12(PCD 230)

|

80

|

47

|

|

MO-12

|

21

|

50

|

18

|

17(PCD 340)

|

PT3/8

|

M16

|

3-M12(PCD 200)

|

3-M12(PCD 260)

|

80

|

55

|

|

ML-08

|

14

|

35

|

18

|

11(PCD 243)

|

PT1/4

|

M10

|

3-M10(PCD 136)

|

3-M10(PCD

186)

|

80

|

47

|

|

MOT-04

|

10

|

23

|

13

|

9(PCD 135)

|

PT1/8

|

M8

|

2-M8(PCD 90)

|

|

64

|

47

|

|

MOT-05

|

10

|

25

|

13

|

9(PCD 165)

|

PT1/4

|

M8

|

2-M8(PCD 100)

|

|

80

|

47

|

|

MOT-06

|

12

|

31

|

18

|

11(PCD 202)

|

PT1/4

|

M10

|

2-M8(PCD 134)

|

|

80

|

47

|

|

MOT-08

|

14

|

35

|

18

|

11(PCD 243)

|

PT1/4

|

M10

|

2-M10(PCD 136)

|

2-M10(PCD 186)

|

80

|

47

|

|

MOT-10

|

16

|

40

|

18

|

13(PCD 285)

|

PT1/4

|

M12

|

2-M12(PCD 170)

|

2-M12(PCD 230)

|

80

|

47

|

Subject to technology changes without prior information

Non-standard requirements can be made